About HKT Kabeltechnik

Highest quality and reliability - our claim since 1998.

Corporate values

Modern production processes and seamless quality monitoring contribute to the manufacture of our

our products to meet your highest quality requirements.

All products at all production levels are subject to 100% quality testing.

The result is the highest quality cabling systems according to your wishes and specifications.

Customers with complex tasks have relied on the expertise of HKT-Kabeltechnik GmbH for decades.

of HKT-Kabeltechnik GmbH for decades.

Your specialist for cable assembly made in Germany

Gottlieb-Daimler Str. 1

88451 Dettingen

Deutschland

Tel.: +49 (0) 7354 932 553

info@hktkabeltechnik-hggfdlgd1q.live-website.com

www.hkt-kabeltechnik.de

Alexander Heck,

Commercial Managing Director

Cabling

Defense

Aviation

Custom Support

Training

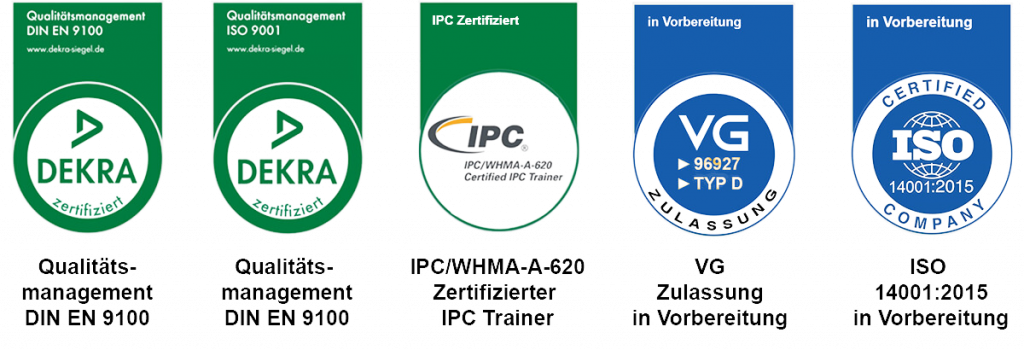

DIN EN ISO 9001 Quality management system

DIN EN 9100 QM system aerospace and defense

Certified quality

Our production facility is certified to several standards:

EN9100 Luftfahrt, DIN ISO 9001, IPC/WHMA-A-620 and VG-Zulassung 96927 Typ D and ISO 14001:2015 is in preparation.

Company history

1998

The company is founded by the managing owner at the Kellmünz site. The most important customer at that time and still today is the world market leader for cargo loading systems in the aviation industry.

1999

In the meantime, production has moved to the Memmingen site. The aim was to be able to meet growing customer requirements with more capacity.

to be able to meet growing customer requirements.

2000

The move to Berkheim takes place, so HKT Kabeltechnik continues to meet customer requirements for more resources.

resources.

2005

For further capacity reasons, the company moves into a second hall at the Berkheim site in order to be able to manufacture large cabling systems for customers in the aviation industry.

2007

Introduction of international standards

2007 / 2008

A plot of land is acquired in the Dettingen industrial estate and a 1,200 m² hall is built there, where HKT has been operating since January 2008.

2016

Two further plots of land with 5500 m²

were acquired. Introduction of an EAP system.

2023

Planning an expansion of the production area by 1200m².